In the world of heavy machinery, excavators stand tall as the unhonored heroes of building and excavation tasks. These mammoth makers are made up of intricate parts and systems, each playing a crucial function in their capability. Amongst these, the final drive assy emerges as the powerhouse that pushes the excavator onward, handling immense lots and tough surfaces with skill. In this comprehensive guide, we explore the functions of the final drive assy, discovering its value, parts, and maintenance essentials.

The Significance of the final drive assy:

At the heart of every excavator lies the final drive assy, a mechanical marvel developed to convert engine power into the rotational force needed to move the maker. Positioned at each track's end, these assemblies are in charge of driving the tracks, making it possible for the excavator to go across numerous landscapes effortlessly. Whether it's browsing rough surface or maneuvering through dense forests, the final drive assy ensures optimal efficiency and flexibility, making it indispensable in the realm of hefty tools.

Elements of the final drive assy:

Comprehending the complex functions of the final drive assy entails dissecting its parts, each playing a crucial duty in the general functionality of the system. The primary elements of the final drive assy include:

Hydraulic Electric motor:

At the core of the final drive assy exists the hydraulic motor, which serves as the driving pressure behind the excavator's motion. Powered by hydraulic fluid, the motor creates rotational force, transmitting power to the equipments and gears within the assembly.

Planetary Equipment System:

Operating in tandem with the hydraulic motor, the global equipment system enhances torque and manages rate, allowing for specific control over the excavator's motions. Consisting of numerous gears arranged in a global setup, this system ensures optimum power distribution and performance, even under hefty tons.

Equipment Reduction Mechanism:

As the hydraulic electric motor rotates, the gear decrease system steps down the rotational rate while boosting torque output. This vital component makes it possible for the excavator to exert substantial force, essential for excavating, training, and performing numerous tasks effortlessly.

Bearings and Seals:

To ensure smooth procedure and long life, the final drive assy integrates excellent quality bearings and seals. These components lessen friction, avoid impurities from entering important locations, and endure the roughness of strong use, ensuring integrity in demanding environments.

Upkeep Basics for Longevity:

Proper maintenance is crucial to ensuring the longevity and performance of the final drive assy. Right here are some essential tips to keep these crucial parts in immaculate condition:

Regular Inspections:

Conduct routine assessments of excavator final drive the final drive assy to recognize any kind of signs of wear, damages, or leak. Addressing issues quickly can avoid expensive repair services and downtime in the future.

Lubrication:

Correct lubrication is critical for lowering rubbing and expanding the life-span of the final drive assy. Adhere to supplier referrals for lubrication periods final drive assy and utilize premium quality oil or oil appropriate for the operating conditions.

Cleaning:

Keep the final drive assy tidy and without particles, mud, and other contaminants that could compromise its efficiency. Make use of a stress washer or air compressor to remove buildup and keep ideal performance.

Keeping track of Temperature level:

Display the temperature level of the final drive assy during operation, as excessive warmth can show underlying problems such as inadequate lubrication or overloading. Deal with any problems without delay to avoid potential damages.

Expert Servicing:

Set up routine servicing by certified service technicians to examine and maintain the final drive assy extensively. Expert maintenance makes sure that all components remain in good condition and operating within specs, minimizing the threat of unexpected failings.

In the elaborate ecosystem of excavators, the final drive assy stands as a testimony to engineering excellence, giving the driving force behind these awesome makers. From hydraulic electric motors to worldly equipment systems, each element plays a essential role in making final drive assy certain ideal efficiency and reliability. By recognizing the significance of the final drive assy and sticking to correct maintenance methods, drivers can make best use of the lifespan and performance of their excavators, paving the way for seamless procedures and unparalleled efficiency in the field.

CONTACT

Fax:+86-750-6310882

Tel:+86-750-6318209 6318263

E-Mail: info@hx-machinery.cn

vivian@hx-machinery.cn

WeChat:+8618825353623

Whatsapp:+8613672844386

Haley Joel Osment Then & Now!

Haley Joel Osment Then & Now! Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Hailie Jade Scott Mathers Then & Now!

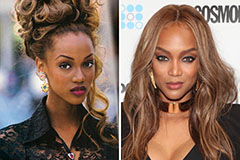

Hailie Jade Scott Mathers Then & Now! Tyra Banks Then & Now!

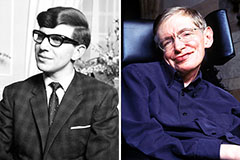

Tyra Banks Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!